行業資訊

數控車床送料機械手常見問題及解決方法

對于數控車床送料機械手的常見故障要針對其具體的原因進行檢修,常見故障有以下幾個方面:

For the common faults of CNC lathe feeding manipulator, it should be overhauled for its specific reasons.

1.減速器聲音不正常。通常是由于齒輪嚙合不好、齒輪或軸承磨損嚴重或斷齒、齒面有粘附物、箱體內有雜物或者軸承游隙太大導致的,需要檢查和清理齒輪、齒面及軸承等。

The sound of the 1. reducer is abnormal. Usually due to poor gear meshing, gear or bearing wear serious or broken teeth, tooth surface adhesion, in the box, or bearing clearance too large, the need to check and clean gear, tooth surface and bearings.

2.減速器溫度過高。可能是潤滑油不干凈或者質量不合格、注油太多或者散熱條件不好導致的,按要求注入潤滑油,清除減速器箱上的浮煤及雜物即可解決;鏈輪軸組溫度過高。可能是軸承損壞或者潤滑油不足導致的,需要更換軸承或者給足潤滑油。

The temperature of the 2. reducer is too high. It may be that the lubricating oil is not clean or the quality is not qualified, the injection is too much or the heat dissipation is not good. It can be injected into the lubricating oil as required to remove the floating coal and sundries on the reducer box; the sprocket shaft group is too high in temperature. It may be caused by damage to the bearing or lack of lubricating oil. It is necessary to replace the bearing or give enough lubricant.

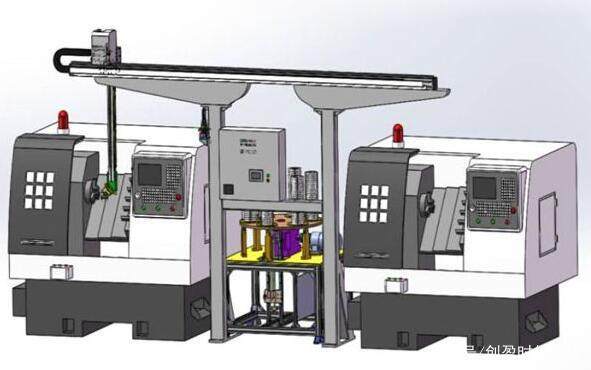

數控機床機械手

數控機床機械手3.刮板鏈跳鏈或掉鏈。可能是由于鏈條卡進金屬物或者刮板鏈太松導致的,需要對金屬物進行清理或者緊鏈;電動機無法啟動或者啟動后緩緩停轉。可能是供電電壓太低、負荷太大或者接觸故障導致的,需要檢查電壓、負荷、控制電路等。

3. chain chain or chain drop chain. It may be caused by the chain card entering the metal or the scraper chain too loose. It is necessary to clean the metal or tighten the chain; the motor can not start or start to stop slowly. It may be the power supply voltage is too low, the load is too large or the contact fault is caused. It is necessary to check the voltage, load, control circuit and so on.

4.電動機溫升高。可能是由于電動機頻繁啟動、長時間超負荷運轉、散熱不良或缺相運行等造成的,應當檢查電動機絕緣、實際電流、風扇等;減速器漏油。可能是密封圈損壞或者上下箱體合而不嚴,各箱蓋壓不緊導致的,需要更換損壞的密封圈,合緊上下箱體以及端蓋螺栓。

4. the temperature of the motor rises. It may be due to the frequent start of motor, long time overload operation, bad heat dissipation or lack of phase operation. The insulation of motor, actual current, fan and so on should be checked, and the reducer is leaking. It is possible that the seal ring is damaged or the upper and lower box is closed and not strict, the pressure of each box is not tight, and the damaged seal ring should be replaced, the upper and lower box and the end cover bolt should be tightened.

在數控車床送料機械手的使用中還要檢查數控車床送料機械手的速度以及數控車床送料機械手內的原料或者成品的厚度,以提高輸送量。對于中間卸料的數控車床送料機械手要盡量加長中間卸料口的長度,延長可卸料時間,同時在鏈條上加裝回料斗,防止出現積料,從而使數控車床送料機械手能夠正常運行。

In the use of CNC lathe feeding manipulator, we should check the speed of the manipulator and the thickness of the raw material or finished product in the CNC lathe, so as to improve the delivery. The numerical control lathe for the intermediate unloading is to lengthen the length of the intermediate discharge port, prolong the discharging time, and add the hopper on the chain to prevent the appearance of the material, so that the manipulator of the CNC lathe is able to operate normally.

文章由:數控車床http://m.cjeh.cn/東莞市周氏數控設備有限公司整理提供,此文觀點不代表本站觀點

以上便是數控車床送料機械手常見問題及解決方法的介紹希望可以幫助到大家,更多的數控知識,請關注我們。

本文標題:數控車床送料機械手常見問題及解決方法 地址:[ http://m.cjeh.cn/xinwenzixun/xingyezixun/596.html ]

新聞資訊

- 數控車床加工雙頭螺栓10/15

- 數控車床哪個品牌好?性價比高03/24

- 適合數控機床加工的零件有哪些?02/05

- 車銑復合機床大概多少錢一臺?01/09

聯系我們

手機:13649862382

電話:13649862382

郵箱:226284020@qq.com

地址:東莞市大嶺山鎮顏屋村顏蓮路86號鑫峰科技園C棟一樓

微信咨詢:

226284020

226284020